Take the PUSH Out of Push-Lock

Struggling with Push-Lok fittings? Say goodbye to wasted time and sore knuckles with Barb-Tech™ Tool’s innovative assembly solutions.

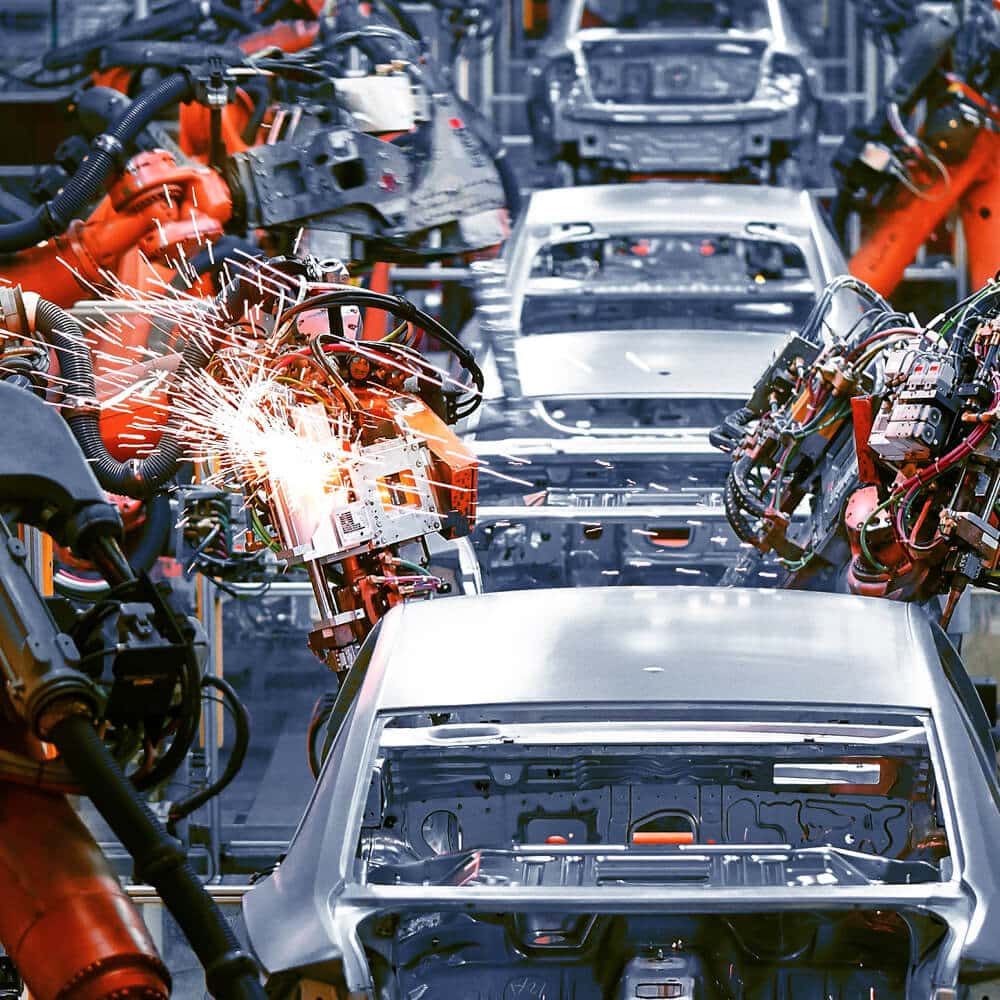

Reduce downtime in injection molding, robotics, pneumatics, industrial, and automation applications with our portable Push-Lok assembly tools.